What is Cold-Chain Logistics?

Cold-chain or temperature-controlled logistics is a supply chain process that guarantees the safe and efficient transportation of perishable items, such as food and pharmaceuticals, by maintaining them at a specific temperature range throughout their journey. It's not just about keeping goods cool, but making certain they're at the right temperature from pickup to delivery.

In practice, it involves a series of refrigerated storage and distribution activities. These can include everything from refrigerated warehouses and distribution centres to refrigerated trucks and shipping containers. The aim is to sustain a constant temperature to avoid product degradation, spoilage or potential health risks.

Modern cold-chain logistics often makes use of sophisticated real-time monitoring and traceability. With this technology, it's possible to track the temperature of goods at any given moment and ensure they're within the acceptable range. This transparency not only increases confidence in the product's safety and quality, but also helps to identify and resolve potential issues quickly.

Why Temperature Control is Critical for Perishable Goods

Maintaining the right temperature is absolutely vital for perishable goods, as it directly influences their quality, safety and shelf-life. Perishable goods, like food, beverages, pharmaceuticals, horticulture and cosmetics, are sensitive to environmental conditions and could degrade rapidly if not transported properly.

- Food & Drink: Temperature control is critical because it prevents the growth of harmful bacteria that can cause foodborne illnesses.

- Pharmaceuticals & Vaccines: If the temperature deviates from the recommended range, the potency and effectiveness of the drugs can be compromised.

- Horticultural: Products like flowers and plants, require specific temperature ranges to stay fresh and maintain their aesthetic appeal.

- Cosmetics: Improper temperature can negatively impact their texture, scent, and overall functionality.

Moreover, the shelf-life of these goods is also directly related to the temperature. A colder temperature slows down the rate of spoilage in many products, thereby extending their shelf life. However, it's not just about keeping the goods cold; it's about maintaining a consistent temperature. For example, temperature fluctuations can cause condensation in some cases, which leads to premature spoilage.

Key Components of Temperature-Controlled Logistics

Each stage of a cold supply chain plays an indispensable role in ensuring that goods are transported in ideal conditions.

Temperature Controlled Vehicles

Temperature-controlled vehicles such as vans, box vans and even fully articulated trucks play a vital role in cold-chain logistics. These vehicles, equipped with specialised refrigeration systems, maintain a constant temperature, regardless of outside conditions.

Many vehicles' feature technology that allows for real-time monitoring and control of the internal environment. Additionally, these vehicles are designed to meet strict regulatory compliance, ensuring safety standards are met. Without temperature-controlled vehicles, maintaining the integrity of temperature-sensitive products during transportation would be nearly impossible.

Temperature Controlled Packaging

While temperature-regulated vehicles guarantee safe transit, it's temperature-regulated packaging that can protect products against varying environmental conditions. This packaging is critical in maintaining product integrity, especially for temperature-sensitive goods like food, pharmaceuticals, and certain cosmetics.

The choice of packaging often depends on the product's specific requirements and the duration of transit. Examples of packaging used in cold-chain logistics include insulated shippers and containers, gel packs, phase change materials and dry ice. Many types of packaging are designed to absorb heat or release it as needed, helping to maintain the temperature within the specified range.

Cold-Chain Storage Facilities

Cold-chain storage facilities play a pivotal role in maintaining the temperature of a shipment when it is not being transported. These facilities, equipped with advanced temperature monitoring and control systems, guarantee that goods maintain the required temperature range when stored, either awaiting further transport or at the final destination.

Storage facilities may include refrigerated warehouses, cold rooms or refrigerated containers, each designed to cater to specific cold-chain requirements. To enhance efficiency, these facilities often employ automated systems for inventory management and tracking.

Temperature Monitoring and Tracking

Monitoring and tracking temperatures is a vital aspect of cold-chain logistics, guaranteeing products such as food, pharmaceuticals, horticulture, and cosmetics maintain their necessary conditions during transportation. This process involves the use of advanced technology and equipment to accurately measure the temperature inside transportation units.

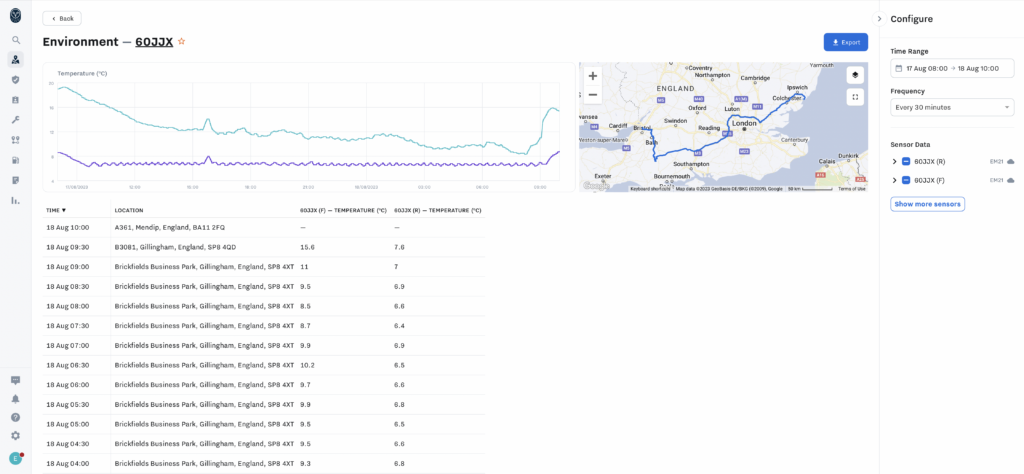

Software like Samsara’s fleet management system allows hauliers and consignors to monitor the location and temperature of their shipment in real time, relaying critical information on the supply chain.

Technologies like this can also produce detailed reports of temperature conditions along the journey, allowing those who receive the goods to precisely review their shipment. This plays an important role in regulatory compliance, allowing companies to prove that their products have been stored and transported within the required temperature range.

Cold-Chain Logistics Industry Use Cases

Cold-Chain for Food and Drinks

When it comes to the food and beverage industry, there's an important role played by cold-chain logistics in guaranteeing freshness and safety. This logistical system works by maintaining a constant, cool temperature from production to consumption. It's vital for perishable products such as fruits, vegetables, dairy, meat and seafood.

Even beverages, particularly craft beers, rely on cold-chain logistics. Temperature fluctuations can affect their taste and shelf-life. Companies in the food and beverage sector invest heavily in cold-chain logistics because it's not just about maintaining quality; it's also about consumer safety. A reliable cold-chain ensures that products are safe to consume, maintaining public health while preserving the brand's reputation.

Cold-Chain Logistics for Pharmaceuticals

Pharmaceuticals' reliance on cold-chain logistics is crucial, as these life-saving products often need to be kept at precise temperatures to maintain their efficacy. This industry uses specialised packaging and refrigerated transportation to guarantee that temperature-sensitive medications, such as vaccines and biologics, are kept within a specific range.

With the global pharmaceutical market growing, the demand for reliable cold-chain logistics has surged. This necessitates constant monitoring, efficient transportation, and meticulous handling. Failure to do so can lead to product degradation, rendering them ineffective or even harmful.

Cold-Chain Logistics Regulations and Compliance

Strict regulations and compliance measures govern cold-chain logistics, given the vital nature of the products they handle, like food, pharmaceutical goods, cosmetics, and horticulture items. These regulations guarantee the quality and safety of goods as they move from producer to consumer.

Various international bodies establish these rules; the Transported Asset Protection Association (TAPA) serves as a prime example. It publishes standards, training, shares incident intelligence and provides route planning, and equips members with networking tools. Each of these elements is designed to lessen risk and prevent loss. Specific to the pharmaceutical industry, the World Health Organization (WHO) issues guidelines for the transport and storage of drugs and vaccines.

Compliance with these regulations is essential. Failure can result in fines, damage to a company's reputation or harm consumer health. Hence, companies often use technology like temperature monitoring devices and digital logs to stay compliant. Innovation in the industry is making compliance easier and more efficient, streamlining the cold-chain logistics process.

The Global Importance of Cold-Chain Logistics

Cold chain logistics play an essential role in today's global economy, ensuring the freshness and safety of various goods. Its significance spans across industries like food and beverage, pharmaceuticals, horticulture, and cosmetics. The technology, regulations, and challenges involved in maintaining these temperature-controlled supply chains are complex. Yet, they're indispensable for product integrity and consumer health. Understanding cold-chain logistics is key for businesses wanting to effectively navigate this intricate, yet indispensable sector.

We're ready when you need us